IR-GAS-9001 Syngas continuously monitoring system

Online rack type IR-GAS-3100 Syngas Analyzer

Juni 6, 2017

Pemantauan Konsentrasi Debu LSS2004

Juni 6, 2017IR-GAS-9001 Syngas continuously monitoring system

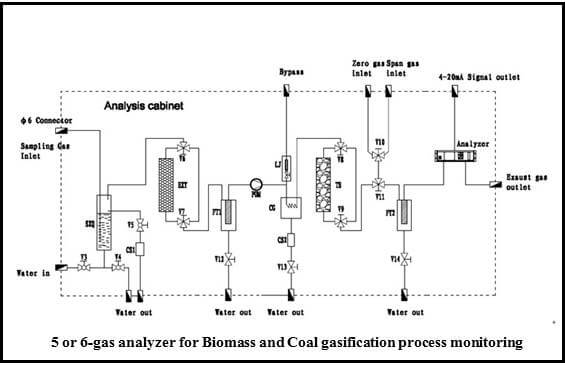

(Sistem analisis gas online profesional untuk pemantauan terus menerus terhadap proses gasifikasi Biomassa dan batubara)

Analysis Systems are available for Biomass and coal gasification processes (up to 6 gases) O2 - CO2 CO - CH4 - CnHm - H2 + BTU calculation

Gas analysis systems merupakan alat untuk membantu anda :

- Untuk mengecek apakah gas tersebut masih diproduksi untuk memutuskan kapan lahan bisa reklamasi

- Untuk memeriksa kualitas gas yang dihasilkan sebelum digunakan dalam beberapa proses industri

- Untuk terus memantau efisiensi instalasi scrubber H2S

Heavy industrial instrumentation cabinet for indoor installation *Mechanical specifications :

- Dimensions : height 1600mm x width 600mm x depth 600 mm

- Weight = approx. 165 kg (with instrumentation)

- Ingress protection : IP54

- Metal plate thickness: 2 mm

- Glass thickness front door: 5 mm

- Colour : RAL 7032

Environmental operation conditions :

- Temperature : +5°C to + 45°C (indoor installation)-25°C to +45°C (with heater/ventilation option for outdoor installation)

- Relative humidity : 0 – 95 % non condensing

- Pressure : 800 – 1200 hPa

Electrical specifications :

- Main power supply 220 VAC-50 Hz with circuit breaker 32A

- Auxiliary power supply for internal fluorescent tube lightening, with circuit breaker 16A

- Auxiliary power supply for gas cooler, with circuit breaker 16A

- Wiring block (accessible via rear door) for : connections of analogue and digital output signals from analyser connection for power supply optional power relays

- 2x opening for cables in the bottom rear plinth (for 220 VAC, RS232, 4-20mA, digital contacts)

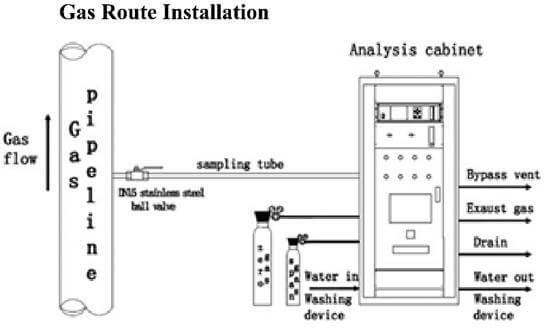

Pneumatic specifications :

- Stainless steel connector for gas inlet, gas outlet, zero air inlet and calibration ports

- Stainless steel connectors on drain

- Diaphragm gas sampling pump 2L/min @ -300 mbar (option if gas pressure <+50 mbar)

- Manual valve for measure/calibration selection

- Pressure reducer on gas sample/calibration inlets set @ +20 mbar

- Flow meter

Gas sampling and conditioning (accessible via the internal access front door) :

- Pre-filtration by coalescing filter with peristaltic pump for continuous condensate removal

- Peltier gas cooler with digital temperature controller and peristaltic pump for continuous condensate removal; gas dew point controlled @ +4°C ± 0,2°C

- H2S Scrubber on gas venting to atmosphere

IR-GAS-9001 Syngas continuously monitoring system

.................

.................

| Gas name | Symbol | Measuring principle | Range1 | Resolution | Accuracy | T90 |

| Oxygen | O2 | Fuel cell | 0-25% | 0.01% | ±2% FS | < 15 s |

| Carbon dioxide | CO2 | NDIR | 0-30% | 0.01% | ±2% FS | < 10 s |

| Methane | CH4 | NDIR | 0-10% | 0.01% | ±2% FS | < 10 s |

| Carbon monoxide | CO | NDIR | 0-40% | 0.01% | ±2% FS | < 10 s |

| Hydrogen | H2 | Thermal conductivity | 0-50% | 0.01% | ±2% FS | < 10 s |

| Hydrocarbons | CnHm | NDIR | 0-10% | 0.01% | ±2% FS | < 10 s |

Professional online gas analysis systems for continuous monitoring of Biomass and coal gasification processes (1.2meter cabinet)